DENTAL PACKAGING

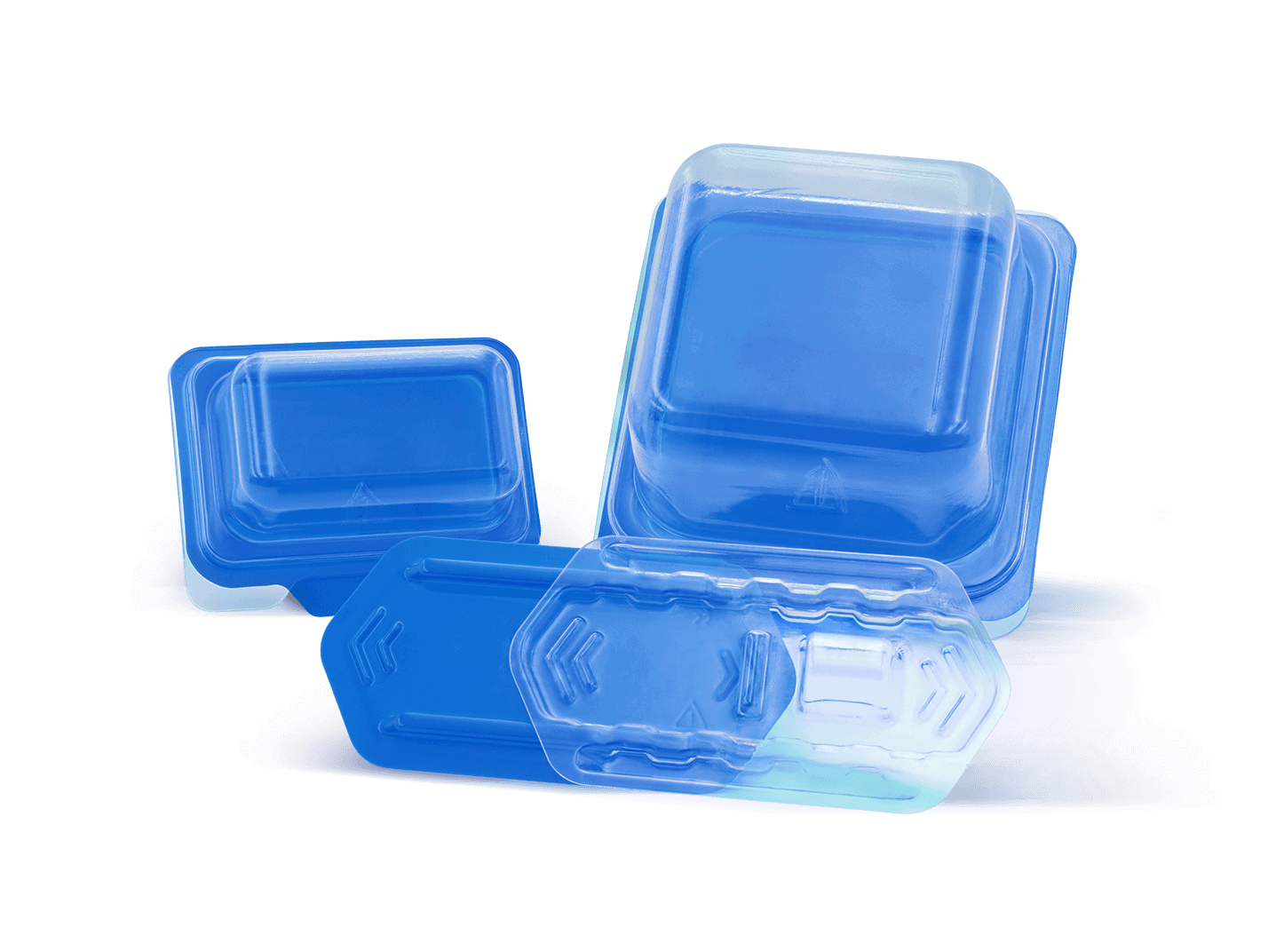

Brentwood’s designers have extensive knowledge of designing custom packaging for the dental industry. We understand that patients require custom solutions for abutments, dentures, implants, and orthodontics, so we design packaging with flexible footprints to fit a variety of different applications.

Brentwood’s designers have extensive knowledge of designing custom packaging for the dental industry. We understand that patients require custom solutions for abutments, dentures, implants, and orthodontics, so we design packaging with flexible footprints to fit a variety of different applications.

MATERIALS

Choosing the appropriate plastic material for your application is an essential step in developing a successful finished part. Each material has its own characteristics, properties, and strengths. Therefore, many factors can influence material selection, ranging from performance to appearance to cost. By working with you to understand the parameters of your project, we can help you choose the best, most cost-effective method to achieve your goals and meet regulations. Learn more about the top materials for medical device packaging.

IN-HOUSE SERVICES

PART DESIGN

Brentwood collaborates with each customer to develop the right packaging solution for your unique needs. Our team of skilled designers, tool engineers, and CNC programmers works to ensure that the custom-tailored design meets your requirements for performance, functionality, and product protection.

PROCESS DESIGN

Our internal project management team is well-practiced at working with complex timelines and deadlines designed to get your product to market. We ensure the process flows smoothly from the first tooling order through final delivery. After that, project management works directly with our customer service team to make sure you can easily reorder parts.

TOOLING

After collaborating with you throughout the design, prototyping, and approval processes, we utilize the knowledge gained to develop high-quality production tooling. All production tooling is produced using top quality materials and is precision machined to the highest tolerances. Post-production, all tools are carefully stored and maintained for future runs.

QUALITY PLANNING

Brentwood’s quality management system is integrated into every step of the development process, guaranteeing consistent products that meet or exceed your expectations. With the end user in mind, we continue to innovate in research and design, providing efficient packaging that simplifies handling and reduces material use.

TOUR OUR CLEANROOM

Brentwood’s cleanroom manufacturing facility offers 30,000 ft² of ISO Class 7 (10,000) certified space, equipped with advanced technology to support both thermoforming and injection molding. With integrated automation—conveyors, stackers, and robotics—we help accelerate your speed to market, manage high-volume production, and maintain exceptional quality standards.

QUALITY CERTIFICATIONS

Brentwood is committed to delivering products that meet or exceed each customer expectation. We maintain programs designed to prevent pollution and to protect the environment, the health of our employees, our customers and the surrounding communities. Brentwood strives for continual improvement of its operations in a manner that not only complies with environmental laws, regulations, and other requirements, but also demonstrates sound environmental stewardship and maintains a positive relationship with the community.